MAGpro Specifications

Production Process

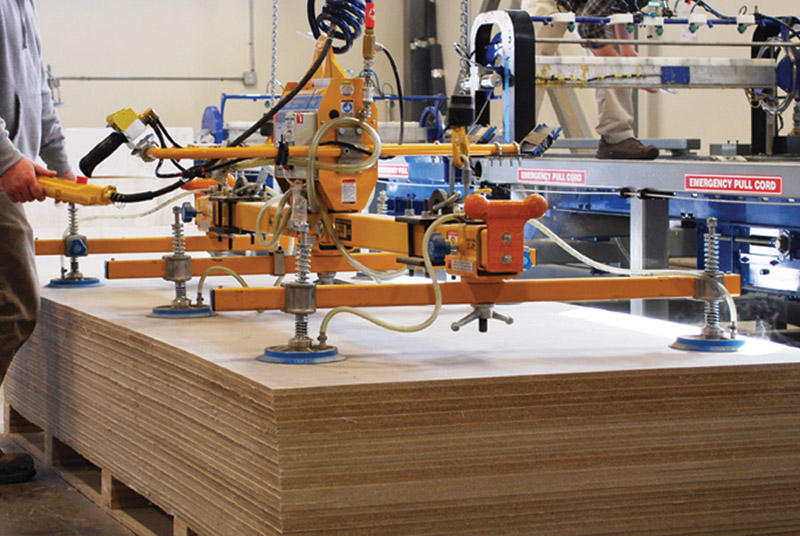

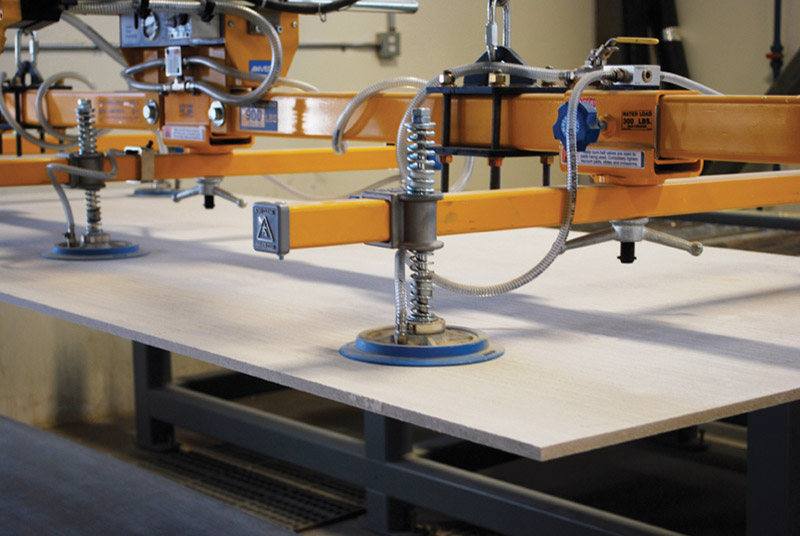

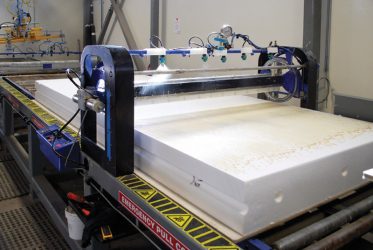

Automated Equipment

Custom design with computer controlled accuracy

MAGpro’s manufacturer, Titanwall Technologies Inc. is leading the industry with its sophisticated equipment allowing them to deliver the highest quality panel in the market today. Production begins with a process that glues the different components of the panel together. The adhesive mixture is adjusted according to the ambient temperature and humidity. It is applied by a computer controlled process that delivers an even coating of glue via 226 glue nozzles and water jets.

After the glue is applied, the panel components are rolled into a large hydraulic press that applies an even level of pressure to the top and bottom surfaces of the panel. The hydraulic press is computer controlled to ensure a uniform panel thickness. Pressed panels are squared and edged by a large format CNC Milling Machine to ensure tolerances of 0.030 inches.

R-Values

Lengths: 8, 9, 10, 12 ft individual panels

MAGpro offers a variety of different lengths and thicknesses to suit all structures. Specific to engineering requirements, we also offer panels with centre splines which results in panel splines at 2′ OC, this method is typically used below grade when backfill heights are over 6′ 6″, these panels are know as “X-Panels”.

Custom and “jumbo” sizes can be fabricated

| Thickness | R-Value | Common Uses |

|---|---|---|

| 4.5” | 16 | Cladding, Fences, Interior Walls, Sheds & Garages |

| 6.5” | 24 | Cladding, Exterior Walls, Basement Floors |

| 8.25” | 34 | Basement Walls, Larger Shop Walls, Roofs |

| 10.25” | 43 | Roofs |

Technical Specifications

Certified testing, Engineered specifications.

MAGpro TECHNICAL SPECS.

| Composition | MgO, MgCl, saw dust, Fiber glass non-woven mesh, talc and other nonhazardous ingredients for fillers |

| Compression Strength | > 7 Mpa |

| Impact Strength | >4 KJ/m2 |

| Tensile/Traction Strength | > 5 M Pa |

| Flexural/Bending Strength | >1 2 M Pa |

| Penetration Strength (Screw-withdrawal force) | >40 N/mm |

| Nail Holding | >40 N/mm |

| Humidity Absorption | ~ 26% de maximum saturation (low absorption rate) |

| Wet Expansion | <0. 5% |

| Dry Shrinking rate | <0.3% |

| Thermal Conductivity | ~ 0, 225 (W/mK) |

| Thermal Resistance | 1.1 4m2 k/w |

| Thermal dilatation | up to 0.08% |

| Standard Thickness | 12mm |

| Dimensional Tolerance (max) | Thickness 0.2mm / width 2mm / length 3mm /square 3mm |

| Asbestos Analysis | None |

| Chlorine Ion content | < 10% |

| Formaldehydes Analysis | < 0.5 mg/L (not used in the process) |

| Density | 900 – 1100 Kg/m3 |

| Frost resistance | Not water/ice formation on the surface |

| Mould resistance (ASTM G21-96) | Rate:0 (no observation under microscope 50X on 28 days) |

| Surface alkalinity | 10-12 Ph |

| Moisture content | <8% |

| Surface type | Smooth side and fine uniformed textured side |

| Fire resistance | Based on 12mm sheet, more than one hour |

| Color | Light Gray |

MAGpro SIP TECHNICAL SPECS**

| Sound Transmission | STC = 24 |

| Fire Resistance | 1 hour |

| Axial Compressive Load | >238 kN/m-width |

| Transverse Load | |

| – Stiffness | >234 kN/m2 |

| – Ultimate Load | >8.8 kPa |

| Racking Load | >23.8 kN/m2 |

| Dimensional Tolerance (max) | Thickness 2mm / width 2mm / length 3mm /square 3mm |

| Weight | 6.3 psf |

| ** Based on 4′ x 8′ x 6.5″ panel | |

| EPS type 1:0.9 pcf |

Fire Performance

MAGpro Panel Fire Rating

MAGpro panels feature zero smoke contribution and zero flame spread. Panel assemblies are fire rated. The images above are of a structure which had been designed and built using 50% MGO panel and 50% conventional materials. The conventional half of the building took less than 60 minutes of burn time to be reduced to ashes, whereas the MGO segment stood firm as the fire itself died out.

| TEST DATA / STANDARD | TEST TITLE | RESULTS / COMMENTS |

|---|---|---|

| ASTM E84 | Standard test method for surface burning characteristics of building materials. | – Intertek Project No. 309816SAT-001. – Flame spread Index & Smoke Developed Index Results were zero. |

| ASTM E119-09C | Fire tests of building construction and materials. | – Intertek Project No. G100121036COQ-002B rev 1 (1 hr fire rating) |

| ASTM E119-09C | Fire tests of building construction and materials. | – Intertek Project No. G100121036COQ-002A (2 hr fire rating) |

| CAN/ULC S124-M85 | Standard method of test for the evaluation of protective coverings for foamed plastics. | – Intertek Report No. 3126866COQ-005A Titan Cementitious Board achieved Class A rating |

Occupant Health

Healthy, comfortable & safe…

MAGpro offers much more than structural superiority as it has no nutrients to feed mold or insects, it has fire ratings up to two hours, has a zero flame spread and no off-gassing and the material is virtually VOC-free, all this creates optimal indoor air quality and a much safer building to occupy.

- Magnesium Oxide SIPS have no nutrients to feed mould or insects

- No off-gassing – inert material is virtually VOC-free

- Snug, comfortable and quiet space